Menu

Menu

Menu

Menu

Using Infracont SGrain is very easy to understand and learn for any user

With the InfraCloud application Infracont SGrain is accessible and manageable from a computer, phone or tablet.

Infracont Sgrain can be operated from a 12V power supply (e.g. a car cigar lighter or external power bank)

Our calibrations ensure accurate and reliable measurements of whole grain cereals, oil seeds and flour

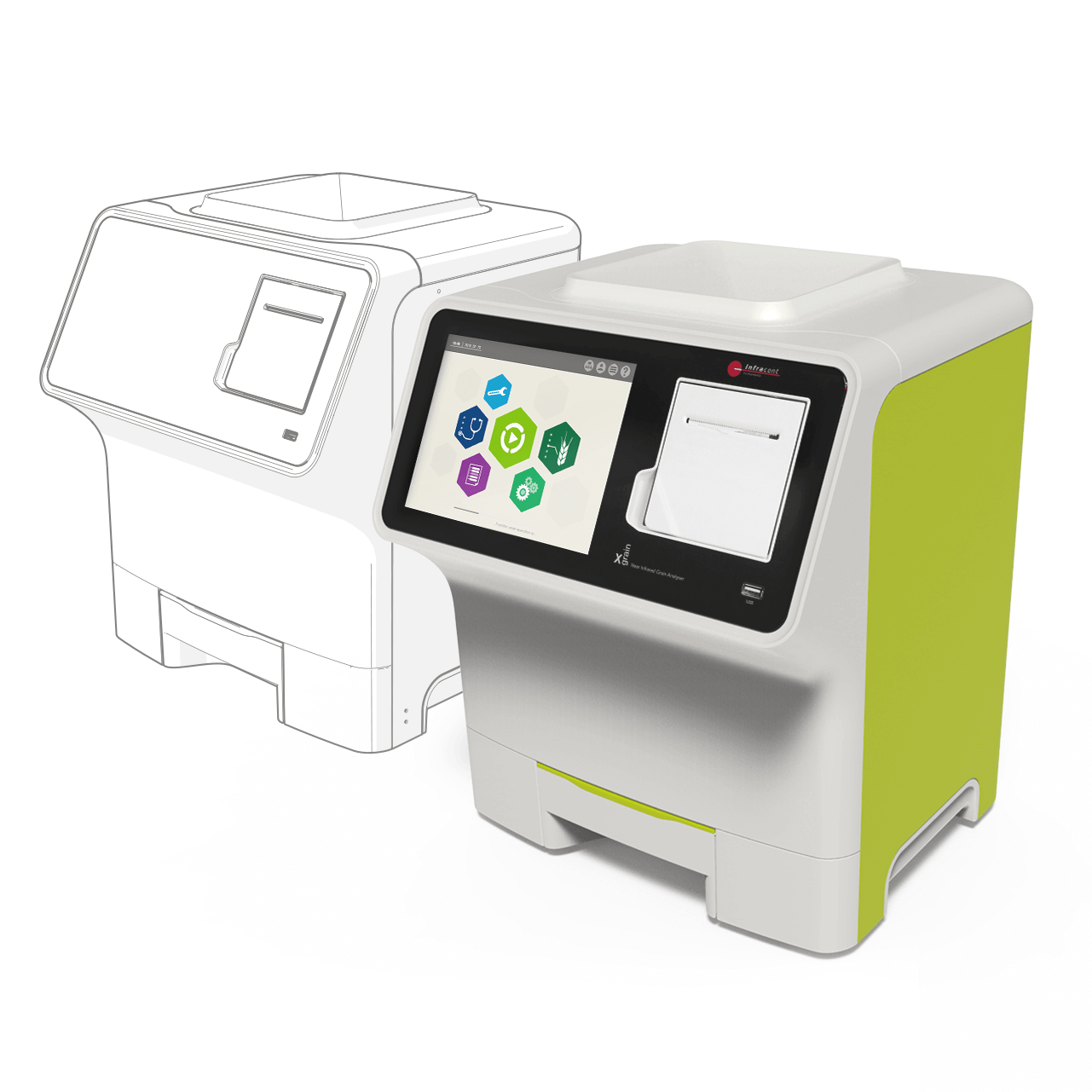

Infracont SGrain is the only portable grain analyser in the world that provides the highest accuracy by applying a high-precision scanning grating monochromator optics inside. The unique optical technology of Infracont called SBCS - Single Beam Compensation System ensures the excellent short and long-term stability of SGrain.

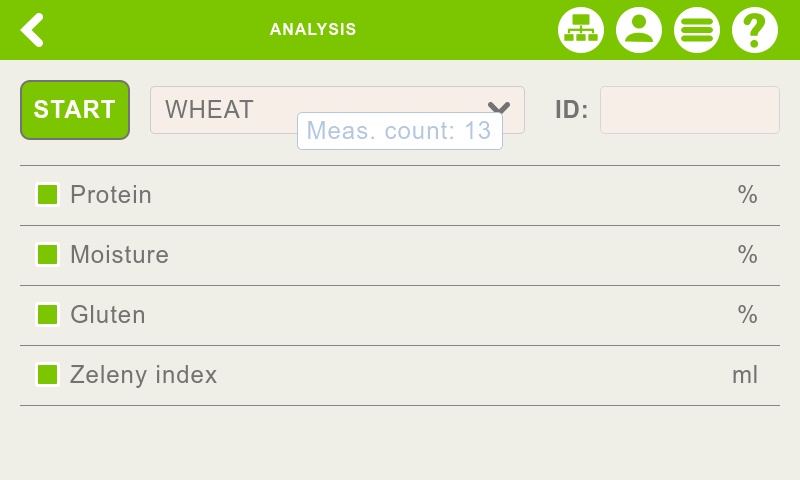

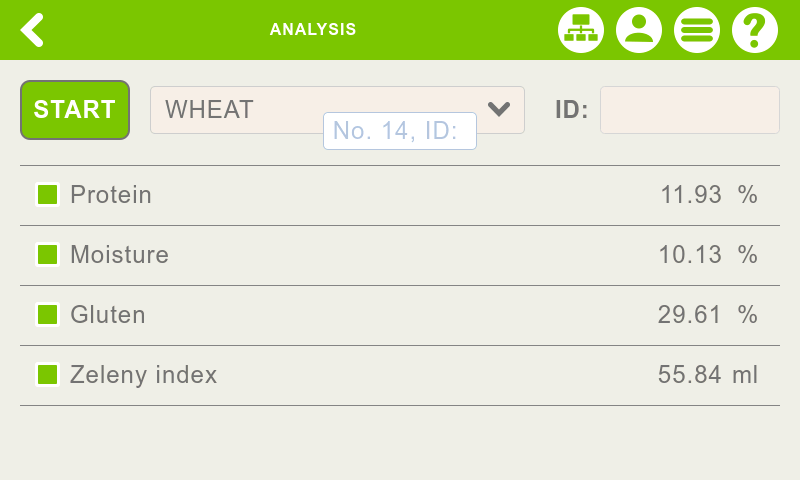

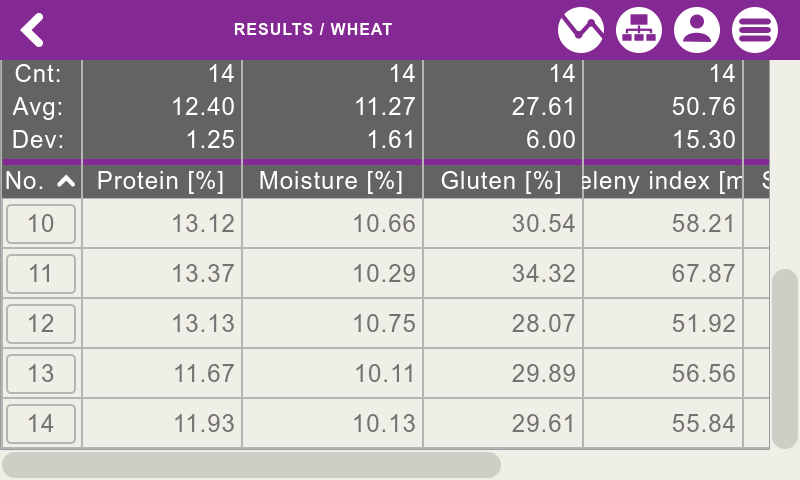

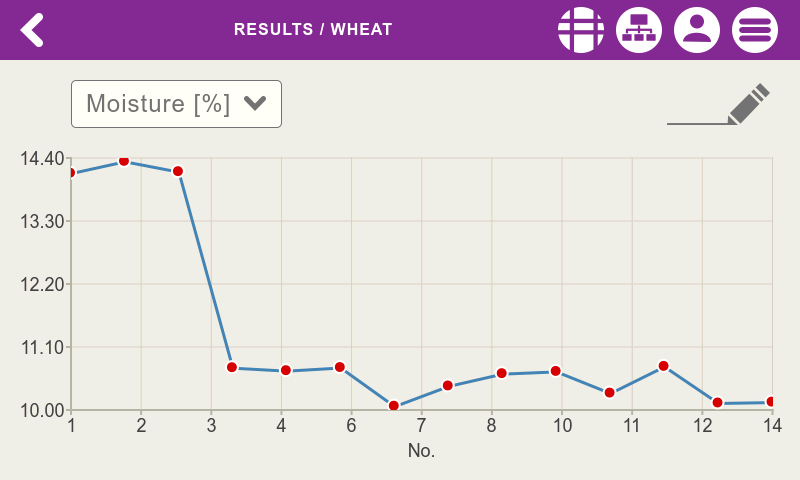

Infracont XGrain and SGrain instruments can be used to analyse the composition of grain and flour without sample preparation. The devices primarily serve to measure protein, moisture, gluten, ash, and oil content, but the Zeleny index can also be measured.

Main application areas of the instruments are:

Infracont XGrain and SGrain instruments are spectrophotometers operating in the Near Infrared (NIR) wavelength range. Infracont grain analysers are transmission mode (NIT - Near Infrared Transmission) instruments that apply light of 780-1064nm wavelength range for the measurement. Some biological materials, like grains and flours transmit light of the above wavelength range in a measurable extent. The instruments scan the material to be analysed and measures the intensity (spectrum) of the transmitted light at several wavelengths. The measurement of the spectrum is done at some selected wavelengths: the light of these wavelengths are produced by a so called scanning grating monochromator.

Based on the light intensities measured by a photodiode, the built-in computer calculates and displays the characteristics of the analysed material. Before the analysis we have to determinate the mathematical correlation between the spectrum of the transmitted light and the component to be measured in advance – this mathematical equation is called calibration. For each product and component different calibrations are needed. Developing a new calibration requires the measurement of the spectra of a large number of samples analysed with ‘traditional’ methods in laboratory. We calculate the calibrations based on these spectra. The instruments can only measure a component of a product after installing the relevant calibration.

Instruments equipped with a scanning grating monochromator represent the premium category of NIR grain analysers as their higher optical resolution enable higher accuracy of measurements.

The ’heart’ of Infracont grain analysers is a unique, patented optical arrangement called ‘SBCS’ – Single Beam Compensation System.

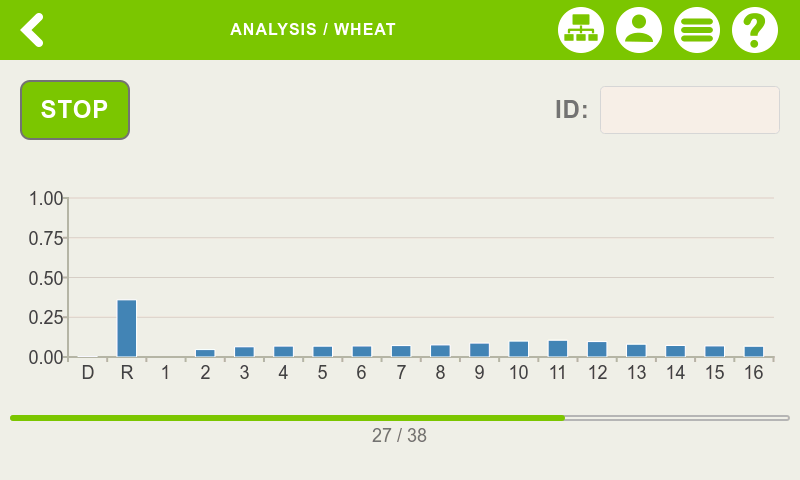

Due to the samples’ granularity and inhomogeneity related to the size of the light beam one measurement does not give a satisfactory result: to get an acceptable accuracy and repeatability we have to average the results of hundreds of elementary measurements. ‘Traditional’ instruments divide the sample into sub-samples and measure these sub-samples or move the sample and measure it on more spots to reach a representative sampling. These methods require usually complex and expensive mechanical solutions.

In case of quantitative analyses, where not only the type of components but also their percentages have to be determined, very stable and accurate analyses are required. Stability can be achieved only if we compensate the changes of the measurement system (e.g. warming up, changes of parts, etc.) with simultaneous measurement of a very stable optical element (optical standard). ‘Traditional’ instruments do this usually by implementing 2 measurement ‘channels’ or doing 2 consecutive measurements:

- the 1st solution is expensive any only acceptable if the 2 channels are absolutely equal,

- the 2nd solution can’t be a perfect solution theoretically because of the time elapsed between the 2 measurements.

Our patented optical arrangement SBCS is different from all of the above because it applies only one optical channel and the elements of this channel are rotating. This means that by SBCS representative sampling can be achieved by moving the light and not by moving the sample: a high speed rotating light beam scans the sample on a large surface.

The light beam measures the sample at 16 different sequential spots and in each cycle it measures the transmission optical standard too. The speed of the rotation ensures the simultaneity of the representative measurement of the sample and that of the transmission standard.

This simultaneity and the optical arrangement applying only one optical channel result in perfect compensation.

Infracont develops calibrations for Infracont grain analysers with Partial Least Squares (PLS) or MLR (Multiple Linear Regression) method, based on sample series analysed in laboratory. The calibrations are transferable from one instrument to another. The instruments are delivered with the calibrations installed according to the requirements of the customers.

The list of the available calibrations can be downloaded here.